Concrete built to last—longer service life, fewer repairs, and lower lifecycle costs.

Finish guides, CEU presentations, and proven design outcomes.

Verified test data, submittal packages, and spec support at your fingertips.

Accelerate schedules by up to 7 days. Lifetime moisture mitigation warranty protects against callbacks and flooring failures.

Seamless batch integration, zero extra steps, fewer callbacks.

Better workability, better flatness/levelness, less fatigue on site.

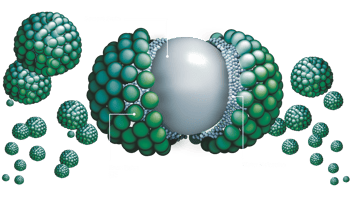

E5® Internal Cure retains mix water at the micro-scale so more cement actually hydrates. Lower capillary tension means fewer micro-cracks, reduced shrinkage/curling, and a more predictable finishing window.

Nano silica reacts with portlandite to form additional C-S-H gel and provides nucleation sites for faster, more complete hydration. The result is a tighter, stronger microstructure with higher near-surface hardness.

Precisely sized particles pack voids and disrupt capillary continuity. Combined with ongoing hydration, this reduces water transport under pressure and supports PRAH-level performance.

Topical chemistry forms a micro-grout at the surface, reducing drag and boosting flatness/levelness. It also helps control surface pH and moisture migration to protect adhesives and coverings.

Viscosity modification increases cohesion in high-flow mixes, limiting segregation and rebound. Finishers get a longer, more controllable window with denser in-place material.

An engineered liquid pozzolan replaces a portion of cement/SCMs, lowering embodied CO₂ while stabilizing workability and strengths across seasons and sources.

E5® systems have demonstrated large reductions in penetration depth (e.g., ~0.89 in control to ~0.19 in with E5® IC + LFA). That pore refinement translates into real waterproofing benefits.

Unlike damp-proofing, E5® acts as a Permeability Reducing Admixture for Hydrostatic conditions (PRAH) in verified testing—supporting below-grade and water-exposed designs.

Densified near-surface zones deliver higher abrasion resistance and dust-proofing, supporting long-wear floors in warehouses, retail, and transit concourses.

Internal curing reduces capillary stresses that drive drying shrinkage, while improved hydration yields flatter, more stable slabs with fewer cracks.

Surface micro-grout and moisture stability give crews back control, enabling higher, more consistent FF/FL without extra topical steps.

A tighter matrix and lower permeability help resist freeze-thaw damage and chloride ingress—key for pavements, decks, and cold-climate assets.

Water intrusion is a silent threat to any concrete structure. It not only compromises the integrity of the slab but can also lead to mold, mildew, and expensive flooring failures, all of which damage your reputation and lead to costly callbacks. Traditional waterproofing methods often rely on external membranes or coatings that can degrade over time and require reapplication. E5 offers a proactive, internal solution.

In high-traffic environments, from warehouses to stadiums, abrasion and wear can cause concrete slabs to deteriorate at a rapid pace. This leads to frequent and costly repairs that eat into your margins and disrupt operations. E5® Nano Silica increases the strength and density of the concrete, making it exceptionally resistant to abrasion, chemical attack, and physical wear.

Moisture vapor migrating through a concrete slab can wreak havoc on flooring systems, causing adhesives to fail, and leading to blistering, delamination, and mold growth. This is a common and costly problem that can jeopardize a project's timeline and budget. E5®'s solutions proactively manage moisture from within the slab.

Shrinkage is an inevitable part of the concrete curing process, but excessive shrinkage can lead to unsightly cracks, joint curling, and a compromised slab. These issues not only require costly fixes but can also affect the integrity of the entire structure and erode a client's trust. E5®'s proprietary technology is a proven solution for reducing shrinkage.

A difficult-to-finish slab can slow down an entire project, increase labor costs, and lead to a subpar surface finish. E5 topical aids are designed to give finishers more control. By improving the workability and lubricity of the concrete surface, our products reduce drag and finisher fatigue, making troweling smoother and more effortless.

For large-scale projects like high-rise buildings and warehouses, concrete must be pumped over long distances without losing its consistency. Poor workability can lead to issues like segregation and slump loss, which cause project delays and add labor costs. E5®’s integral admixtures improve the cohesion and flowability of the concrete mix, making it easier to pump, place, and finish.

The construction industry is under increasing pressure to reduce its environmental impact. Traditional methods, such as using curing compounds, contribute to a project's carbon footprint and produce hazardous waste. E5 offers a sustainable alternative. Our internal curing solutions eliminate the need for topical chemicals, which not only saves you time and money but also results in a significant reduction in CO₂ emissions.

E5®-enhanced concrete with optimized hydration, lower permeability, and longer service life.

Tons of cement saved through optimized hydration and internal curing—lowering embodied CO₂.

Days saved by eliminating wet curing and enabling earlier slab access across projects.

Internal curing for moisture control, flatter slabs, and faster access.

Engineered liquid pozzolan—reduce cement, stabilize workability, cut CO₂.

Micro-grout surface for abrasion resistance and coverings-ready pH/moisture.

Finishing aid that reduces drag—smoother closes without adding water.

Clear, penetrating sealant—dust-proof, low-gloss protection for polished/dyed floors.

Penetrating moisture blocker—densifies existing concrete and protects floor systems.

Viscosity-modifying internal cure for shotcrete—cohesion, pumpability, dense placement.

2025 Copyright. All rights reserved. Site built with Sprocket Rocket & HubSpot. Privacy policy Terms